Pressure Sensing Piezoresistive Fabric

Yunjia’s carbon-based piezoresistive sensing fabric is designed for high-accuracy pressure and force detection in advanced e-textile systems. With tunable surface resistivity from 10⁴–10⁷ Ω/sq, it supports a wide range of circuit and FSR-style sensor architectures.

Built with intrinsically conductive fibers, the fabric maintains stable conductivity and uniform signal response—even after 100+ wash cycles—avoiding the cracking and drift issues common in coated conductive fabrics.

Compared with Velostat and other fixed-structure films, its knitted construction offers superior stretchability and flexibility, ensuring reliable performance in applications such as smart mattresses, pressure-mapping seat pads, and wearable sensors.

Sold by Square Meter

Compare

Product comparison

Give your customers useful information about your products and showcase differences between them.

Electrode

Piezoresistive

Silver

Carbon

0.1 -1 Ω

10⁴–10⁷ Ω

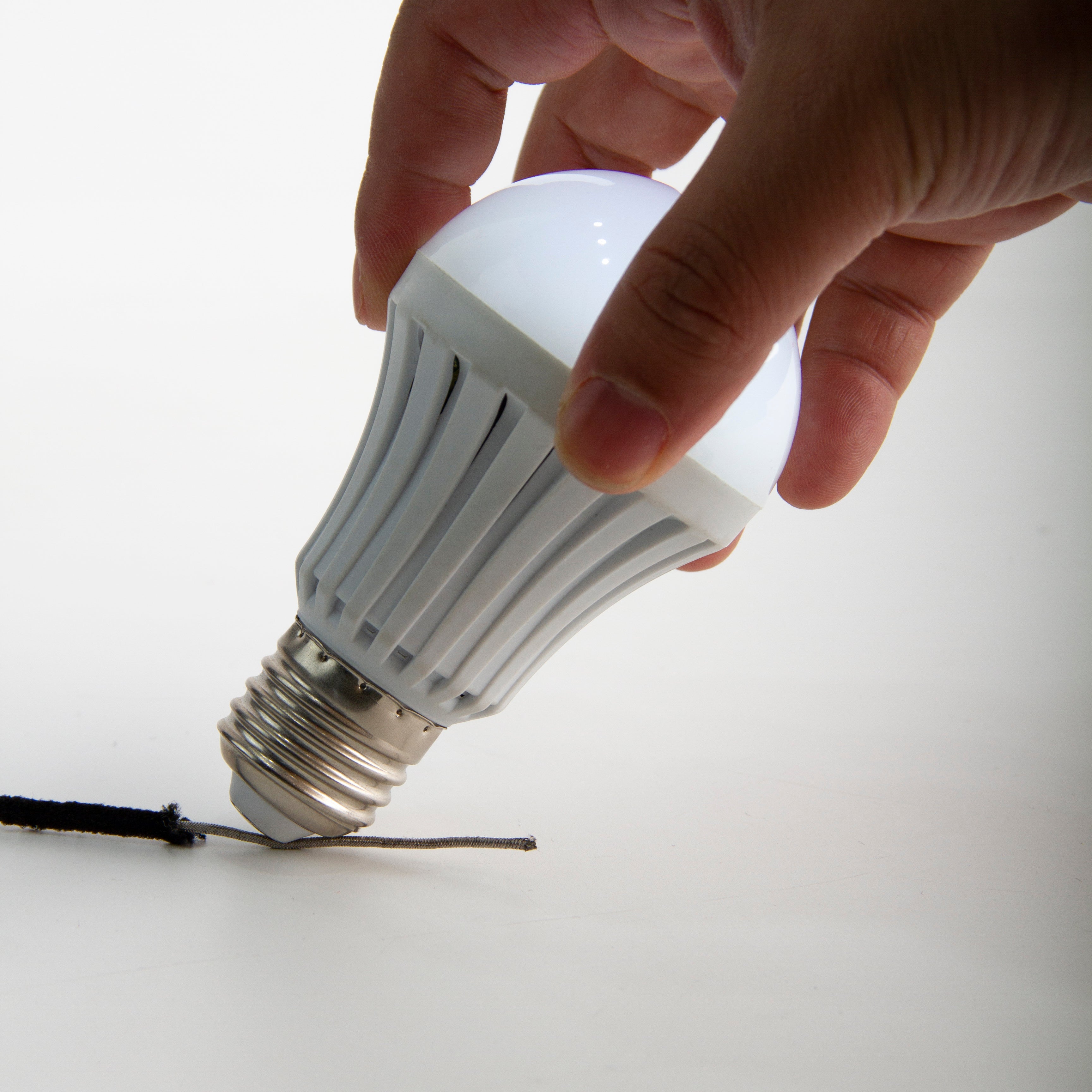

Piezoresistive Resistance Data Sheet

A sandwich structure using conductive PCB silver thin films on the top and bottom layers. Under a 0–2 kg applied force over a 1 cm-diameter contact area, the values shown represent the average of five measurements. This dataset serves as a material performance reference.

Unlike rigid PCB or thin-film materials, conductive textiles provide superior flexibility and stretch, allowing them to bend, compress, and move naturally with the body. This fabric structure maintains conductivity even under repeated deformation, giving textile-based sensors far better durability and comfort for wearable, smart-home, and pressure-sensing applications.

Conductive fabrics offer exceptional conformability, allowing them to wrap, bend, and adapt smoothly to curved or moving surfaces without losing electrical performance. Their textile structure naturally follows body contours or complex shapes, enabling stable contact and consistent signal response. This makes fabric-based sensors far more versatile than rigid PCB or thin-film materials.

Unlike rigid PCB or thin-film materials, conductive textiles provide superior flexibility and stretch, allowing them to bend, compress, and move naturally with the body. This fabric structure maintains conductivity even under repeated deformation, giving textile-based sensors far better durability and comfort for wearable, smart-home, and pressure-sensing applications.

Conductive fabrics offer exceptional conformability, allowing them to wrap, bend, and adapt smoothly to curved or moving surfaces without losing electrical performance. Their textile structure naturally follows body contours or complex shapes, enabling stable contact and consistent signal response. This makes fabric-based sensors far more versatile than rigid PCB or thin-film materials.

FAQ

Does the fabric maintain conductivity after long-term fatigue, folding, or abrasion?

Yes. The conductive network is integrated into the yarn or fabric structure, so it resists cracking or delamination. Unlike thin films or PCB traces, the textile architecture distributes mechanical stress across many fibers, allowing stable conductivity even after extensive folding, rubbing, or mechanical fatigue.

How does humidity, temperature, or sweat affect surface resistance and signal consistency?

Environmental effects vary by material. Carbon-based textiles show minimal drift, while silver or copper coatings may oxidize more quickly. Stainless-steel and carbon-based options offer much stronger stability, with some passing 72-hour salt-spray testing. The best choice depends on the customer’s performance and environmental requirements.

Can the fabric be customized in resistance range, GSM, yarn type, or structure for specific sensing needs?

Yes. We understand that every sensing design is different, and many applications require customized solutions rather than standard products. Our conductive textiles can be tailored in surface resistance, GSM, yarn composition, and fabric structure to meet specific performance targets such as sensitivity, response curve, durability, or integration method.